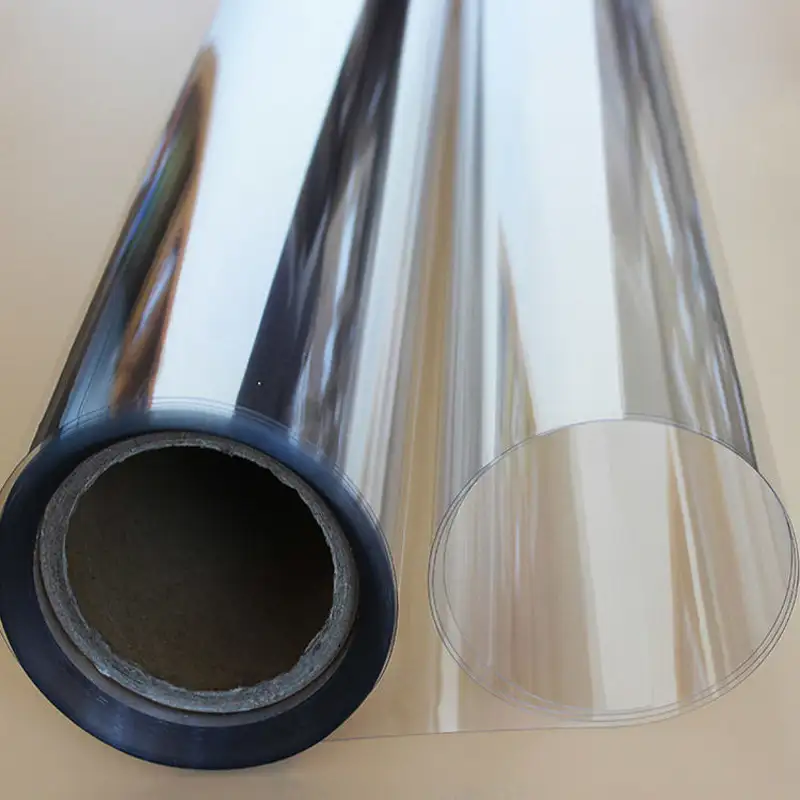

Thermoforming PET Sheets

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? Thermoforming PET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 Thermoforming PET Sheet Roll 熱成形またはブリスター包装用. に関して "Thermoforming PET Sheets", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

What is Thermoforming PET Sheets?

Thermoforming PET Sheets possess excellent material properties, making them widely applicable across various fields. Firstly, PET sheets feature high transparency and gloss, allowing for clear display of packaged contents, which is particularly suitable for applications requiring visual appeal, such as food and consumer products.Secondly, PET material is lightweight yet strong, offering good impact resistance and flexibility, enabling it to withstand mechanical stress during processing and use.

Additionally, PET sheets exhibit outstanding chemical resistance and thermal stability, maintaining performance under high temperatures and chemical exposure, making them ideal for thermoforming processes. PET is also an environmentally friendly material, fully recyclable, compliant with food contact safety standards (such as FDA certification), and meets environmental requirements like RoHS. These properties make Thermoforming PET Sheets an ideal choice for food packaging, medical packaging, industrial components, and more.

Advantages of Thermoformed PET sheets

1. High strength

Thermoformed PET sheets have excellent tensile strength and tensile resistance, can withstand large external forces without breaking, and are suitable for applications that require high strength.

2. Impact resistance

PET materials have good impact resistance, can maintain toughness even in low temperature environments, and are not easy to break. They are suitable for protective packaging or industrial parts.

3. Flexibility

Thermoformed PET sheets have both rigidity and flexibility, can be bent or folded without breaking, and are suitable for thermoforming of complex shapes.

4. Thickness uniformity

High quality PET plastic sheets strictly control thickness during production to ensure uniform thickness of each part of the sheet and good consistency of the product after molding.

5. Dimensional stability

Thermoformed PET plastic sheets have small dimensional changes during processing and use, can maintain stable shape, and are suitable for high-precision molding needs.

6. Wear resistance

PET material has a high surface hardness and good wear resistance, which can resist wear and tear in daily use and extend the life of the product.

7. Lightweight

Thermoformed PET sheet rolls are light in texture and low in density, which can effectively reduce the overall weight of the product while reducing transportation and processing costs.

8. Transparency and glossiness

PET plastic sheets have high transparency and excellent glossiness, which can clearly display the packaging contents while enhancing the appearance of the product.

Application of Thermoformed PET sheets

Thermoforming PET Sheets are widely used in the packaging of various products due to their excellent physical properties, transparency, and environmental characteristics. Below are some typical application examples:

1. Food Packaging

- Trays: Used for the display and preservation of fresh foods, meats, fruits, and vegetables.

- Cups and Containers: Such as jelly cups, yogurt cups, and salad boxes.

- Lids: Used for beverage cups, fast food containers, etc.

- Egg Cartons: Protect eggs from impact while providing clear visibility.

- Bakery Packaging: Such as cake trays and cookie boxes.

2. Medical and Pharmaceutical Packaging

- Medical Device Trays: Used for the packaging of sterile medical instruments, ensuring cleanliness and safety.

- Blister Packs: Used for the unit-dose packaging and protection of tablets and capsules.

- Medical Containers: Such as reagent kits and sample collection boxes.

3. Electronics Packaging

- Protective Trays: Used for anti-static packaging of electronic components, circuit boards, and chips.

- Display Boxes: Used for retail packaging of small electronic products, such as earphones and USB drives.

4. Consumer Goods Packaging

- Cosmetic Packaging: Such as lipstick tubes, powder compacts, and skincare containers.

- Toy Packaging: Used for display boxes or protective packaging of toys.

- Gift Boxes: Used for holiday gifts or promotional items.

5. Industrial Product Packaging

- Tool Packaging: Used for protective trays for small tools or components.

- Automotive Parts Packaging: Such as interior parts and electronic modules.

6. Retail and Display Packaging

- Display Trays: Used for product display and promotion in supermarkets or retail stores.

- Transparent Boxes: Used for the display packaging of stationery, toys, and small household items.

7. Disposable Product Packaging

- Cutlery Packaging: Such as boxes for disposable forks, knives, and straws.

- Travel Kits: Such as toiletry boxes and travel set containers.

8. Specialty Packaging

- Cold Chain Packaging: Used for insulated packaging of frozen foods or refrigerated pharmaceuticals.

- Anti-Counterfeit Packaging: Used for high-end products through special printing or design.

Why Choose Thermoformed PET Sheets?

Transparent and Aesthetic: High transparency and gloss enhance product display.

Safe and Hygienic: Compliant with food contact safety standards (e.g., FDA certification), suitable for food and medical packaging.

Durable: Impact-resistant and chemically corrosion-resistant, suitable for various environments.

Eco-Friendly and Recyclable: 100% recyclable, aligning with sustainable development trends.

Specifications of Thermoformed PET sheets

Specifications 1

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Specifications 2

| Properties | UNIT | METHOD | Virgin PET | Pre-consumer/Post Recycled PET | |||

|---|---|---|---|---|---|---|---|

| Data | (ASTM) | 100% PET | RPET 25% | RPET 30% | |||

| Thickness Tolerance | %/mm | / | ±5% | ±5% | ±5% | ||

| Thickness Range | mm | / | 0.18 – 1.8 | 0.18 – 1.8 | 0.12 – 1.8 | ||

| Width Tolerance | mm | / | ±2mm | ±2mm | ±2mm | ||

| Width Range | mm | / | 200 – 1400 | 200 – 1400 | 200 – 1400 | ||

| Weight Tolerance | % | / | ±3% | ±3% | ±3% | ||

Main PET Plastic Sheet Types

pet-sheet.comを選ぶ理由

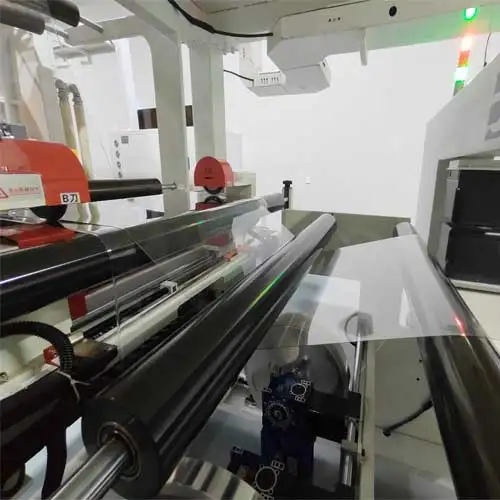

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM