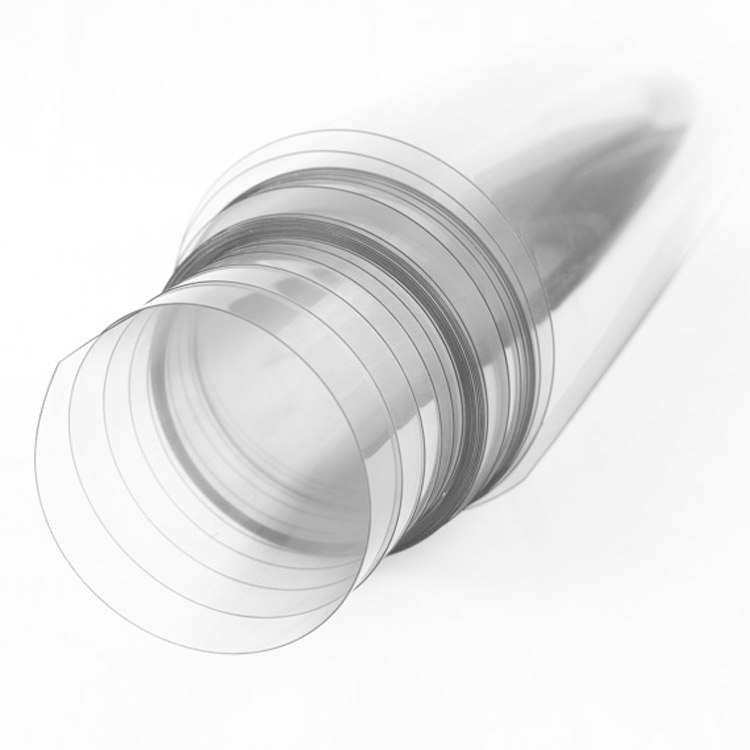

Recycled PET Plastic Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? RPET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 RPET Sheet Roll 熱成形またはブリスター包装用. に関して "Recycled PET Plastic Sheet Rolls", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction Of Recycled PET Plastic Sheet Rolls

Recycled PET (Polyethylene Terephthalate) Plastic Sheet Rolls are eco-friendly, durable, and versatile materials made from post-consumer or post-industrial PET waste. These sheets are widely used in various industries due to their sustainability, strength, and ease of processing. By utilizing recycled PET, these sheets contribute to reducing plastic waste and promoting a circular economy.

Key Features

1. Sustainability

- Utilizes post-consumer recycled PET, reducing dependence on virgin plastic.

- Contributes to waste reduction by repurposing plastic materials.

- Supports circular economy principles by extending the life cycle of plastics.

2. Environmental Benefits

- Lowers carbon footprint compared to sheets made from virgin materials.

- Decreases energy consumption and resource usage in production.

- Addresses plastic pollution by diverting plastic waste from landfills and oceans.

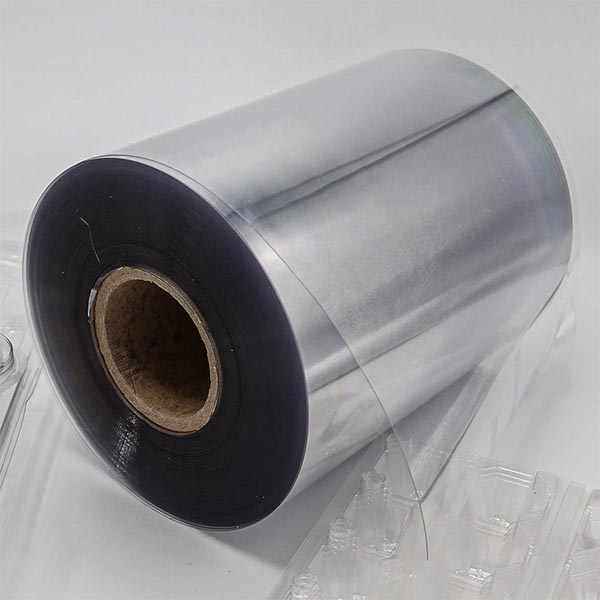

3. Versatility

- Available in various thicknesses and sizes to accommodate diverse applications.

- Suitable for various fields of product packaging.

- Customizable to meet specific requirements in terms of color and other properties.

4. Material Properties

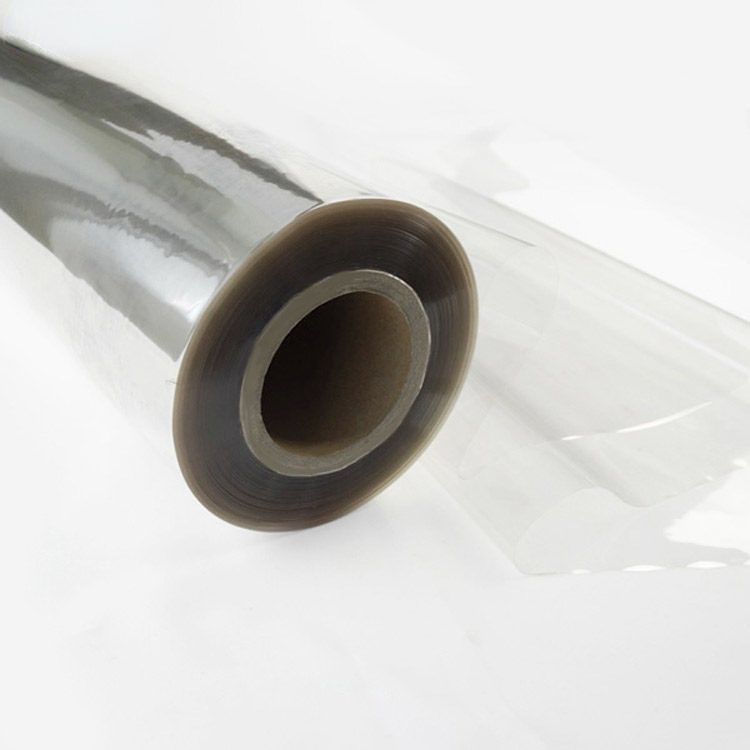

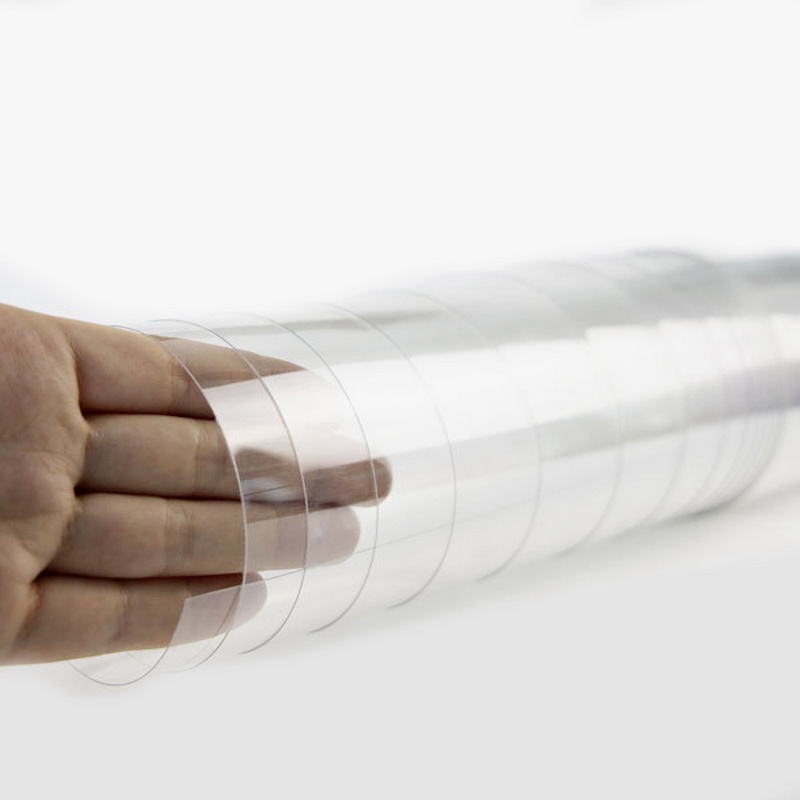

- Retains key properties of PET plastic, including transparency and mechanical strength.

- Resistant to chemicals and moisture, ensuring durability in various environments.

- Potential for modification based on application-specific needs.

Product Advantages Of Recycled PET Plastic Sheet Rolls

1. Eco-Friendly: Made from 100% recycled PET, reducing the environmental impact of plastic waste.

2. High Strength and Durability: Excellent mechanical properties, including impact resistance and tensile strength.

3. Lightweight: Easy to handle and transport while maintaining structural integrity.

4. Chemical Resistance: Resistant to many chemicals, making it suitable for harsh environments.

5. Thermoformable: Can be easily molded into various shapes and sizes for custom applications.

6. Food Grade Options: Available in food-safe grades, compliant with FDA and EU regulations.

7. UV Resistance: Some variants are UV-stabilized for outdoor use.

8. Customizable: Available in various thicknesses, colors, and finishes to meet specific requirements.

Product Applications Of Recycled PET Plastic Sheet Rolls

Recycled PET Plastic Sheet Rolls are widely used in a variety of product packaging fields due to their environmental friendliness, durability and plasticity. Here are some common application scenarios and product packaging types:

| Category | Applications |

|---|---|

| 1. Food Packaging |

|

| 2. Electronic Product Packaging |

|

| 3. Cosmetic and Personal Care Product Packaging |

|

| 4. Pharmaceutical Packaging |

|

| 5. Retail and Consumer Product Packaging |

|

| 6. Industrial Product Packaging |

|

| 7. Environmentally Friendly Packaging |

|

| 8. Special Purpose Packaging |

|

Advantages Summary

- Environmental protection: using recycled PET materials, reducing plastic pollution, in line with the concept of sustainable development.

- High transparency: suitable for packaging that needs to display internal products.

- Strong durability: with good impact resistance and chemical resistance, suitable for a variety of packaging needs.

- Customizability: thickness, color and shape can be customized according to product requirements.

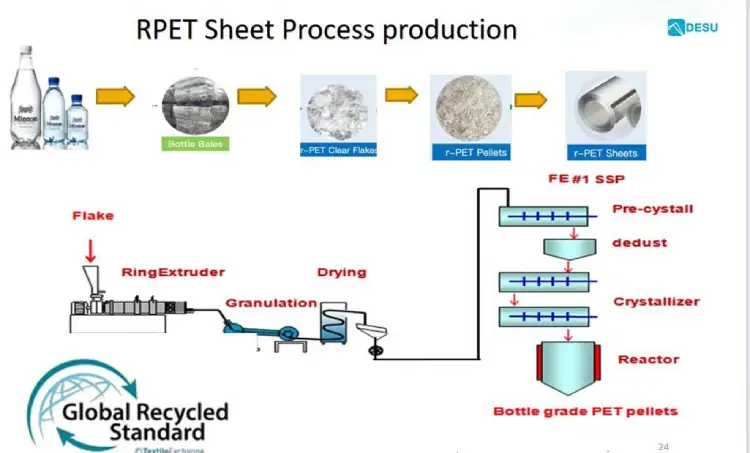

RPET Plastic Sheet Rolls Process Production

RPET (Recycled PET) plastic sheet rolls are made from recycled PET bottles or other PET materials. The process of producing RPET plastic sheet rolls typically involves several key steps:

1. Collection and Sorting: PET bottles or other PET-based waste are collected, sorted, and cleaned to remove contaminants such as labels, caps, and other non-PET materials.

2. Shredding: The cleaned PET bottles are shredded into smaller pieces, often referred to as PET flakes.

3. Washing: The shredded PET is thoroughly washed to remove any remaining impurities, oils, and adhesives. This step is crucial for ensuring that the recycled material is of high quality.

4. Drying: After washing, the PET flakes are dried to remove excess moisture. This helps in maintaining the quality of the final product.

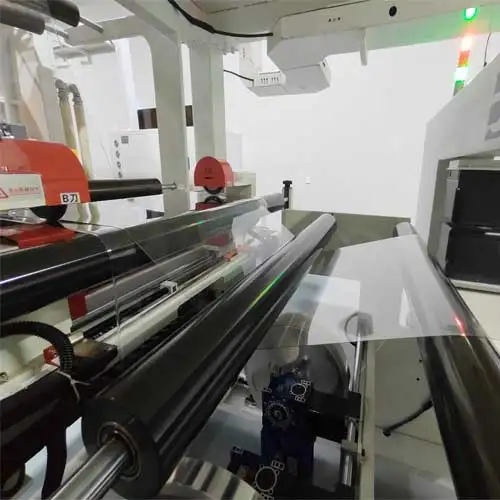

5. Extrusion: The dry PET flakes are fed into an extrusion machine, where they are melted and formed into sheets. The extrusion process helps to mold the melted plastic into uniform thicknesses and widths.

6. Cooling: The extruded PET sheet is cooled to solidify it and achieve the desired thickness.

7. Rolling: Once the sheet has cooled, it is wound into large rolls, ready for use in various applications such as packaging, thermoforming, or further processing.

8. Quality Control: During and after production, the RPET plastic sheet rolls undergo quality control checks to ensure that they meet the required standards, such as thickness, clarity, and strength.

9. Cutting/Customizing (if needed): The RPET plastic sheet rolls may be cut into specific sizes or customized based on the customer’s needs, whether for packaging or other uses.

This process ensures that the RPET plastic sheet rolls maintain a high level of performance while also being environmentally friendly by recycling PET waste.

pet-sheet.comを選ぶ理由

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM