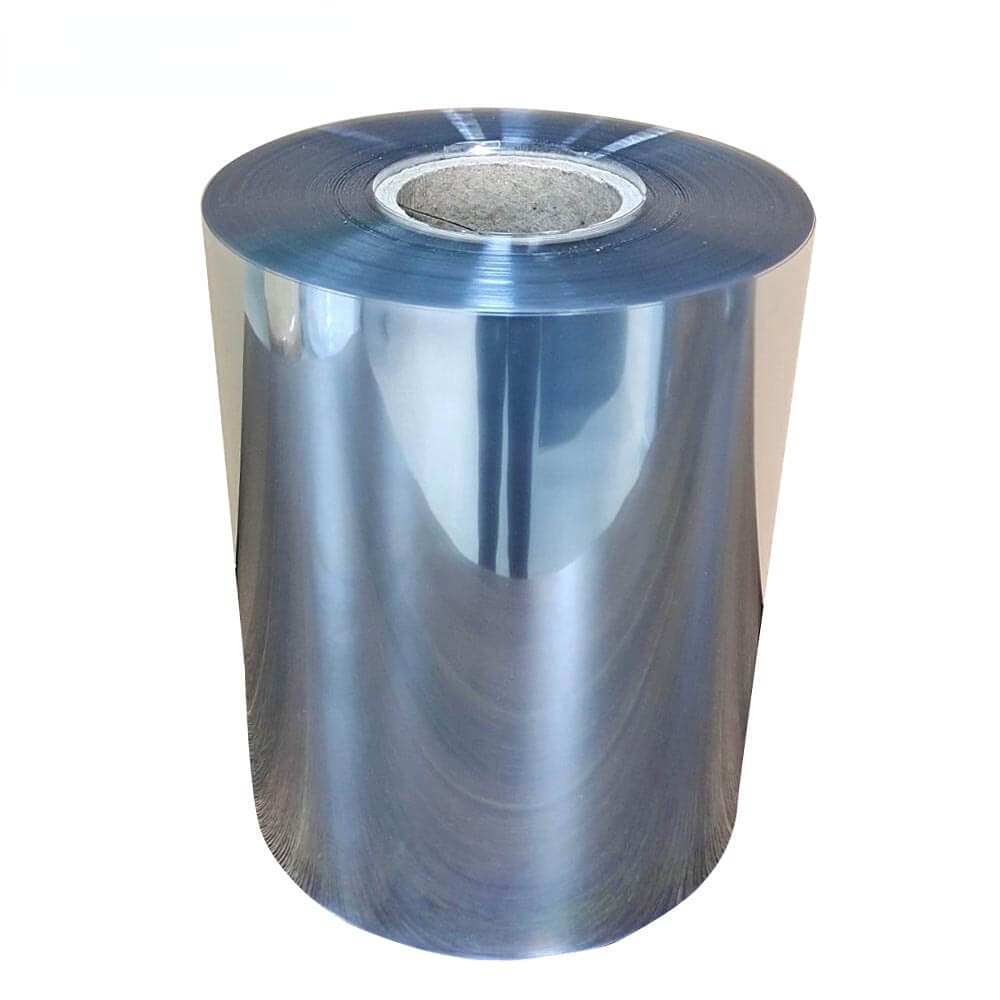

PET plastic sheet rolls

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

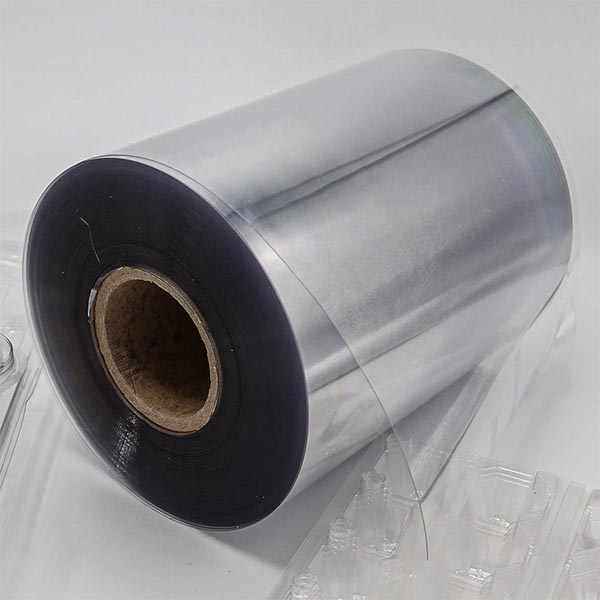

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? Thermoforming PET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 Thermoforming PET Sheet Roll 熱成形またはブリスター包装用. に関して "PET plastic sheet rolls", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of PET plastic sheet rolls

PET plastic sheet rolls are made from polyethylene terephthalate (PET) and are widely used in various packaging and industrial applications. Their characteristics include:

- Heat Resistance: PET has good heat resistance, suitable for high-temperature processing.

- Transparency: Typically offers excellent transparency, ideal for packaging that requires visual display.

- Strength and Toughness: Exhibits high mechanical strength and toughness, providing protection for internal products.

- Environmental Friendliness: PET is recyclable, aligning with sustainable development trends.

5. Recyclability: PET plastic sheet roll is recyclable, in line with the trend of sustainable development, and is favored by the market and consumers.

PET Plastic Sheet Rolls

- Thickness: 0.18-2.0mm

- Width: 300-1400mm

- Color: Transparent or Customized

- Special performance customization: Anti-fog, Printing, Coating, High impact, Waterproof, Oil-proof, Anti-UV, etc.

- Delivery time: 7~15 days since receipt of PO and down payment.

- Payment Accepted: D/A, D/P, T/T, L/C, Westunion etc.

- Samples: Free samples supply

Common applications include food packaging, electronic product packaging, and other consumer goods packaging.

Advantages of PET plastic sheet rolls

The advantages of PET plastic sheet rolls include:

1. Excellent Clarity: PET plastic sheet rolls has provides high transparency, enhancing product visibility and appeal.

2. Good Barrier Properties: Offers resistance to moisture, gases, and UV light, protecting contents from spoilage and degradation.

3. High Strength and Durability: Withstands impact and puncture, ensuring the safety of packaged goods.

4. Heat Resistance: PET plastic sheet rolls suitable for various applications that require high-temperature processing or storage.

5. Lightweight: Reduces shipping costs and makes handling easier.

6. Recyclability: Can be recycled, contributing to sustainability and reducing environmental impact.

7. Chemical Resistance: Resistant to many chemicals, making it versatile for different applications.

8. Cost-Effectiveness: Provides good performance at a competitive price, making it a popular choice for manufacturers.

These advantages make PET plastic sheet rolls ideal for a wide range of packaging and industrial applications.

Application of PET plastic sheet rolls

PET plastic sheet rolls have the following uses:

1. Blister Packaging: PET plastic rolls are used to create transparent blister packs for items like electronics, medical devices, and food products. They offer a secure yet visible packaging solution.

2. Food Trays and Containers: PET plastic sheet rolls are widely used to produce plastic trays and containers for fresh food, such as fruits, vegetables, and bakery items. They are lightweight and provide a barrier that helps maintain freshness.

3. Beverage Lids: PET plastic sheet rolls can be thermoformed into lids for beverage cups, offering transparency and strength to protect the contents.

4. Pharmaceutical packaging: used in the pharmaceutical industry to package drugs and medical devices to ensure product safety and effectiveness.

5. Cosmetic packaging: used for containers and lids of cosmetics and skin care products, providing good sealing and display effects.

6. Electronic product packaging: protect electronic components and equipment from moisture and damage.

7. Industrial component packaging: used to package mechanical parts and accessories to ensure safety during transportation.

8. Label and sticker packaging: can be used to make water-resistant and wear-resistant label packaging.

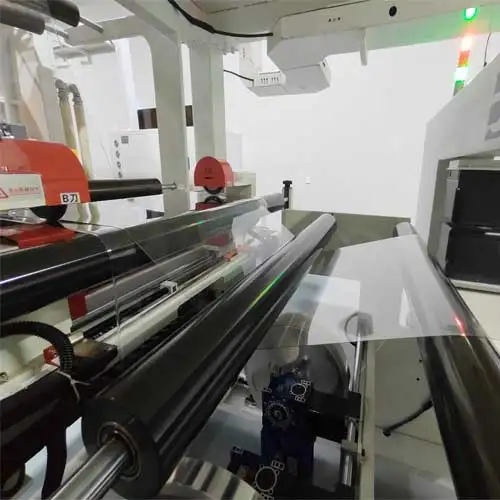

Production and processing of PET plastic sheet rolls

The production and processing of PET (Polyethylene Terephthalate) plastic sheet rolls involve several key steps:

1. Raw Material Preparation: PET resin is produced through a polymerization process, typically from purified terephthalic acid (PTA) and ethylene glycol (EG).

The resin is often in pellet form, which is the starting point for sheet production.

2. Extrusion: The PET pellets are fed into an extruder, where they are heated to a molten state.

The molten PET is then forced through a die to form a continuous sheet.

3. Calendering: The extruded sheet is passed through a series of heated rollers (calenders) to achieve the desired thickness and smoothness.

This process also allows for the adjustment of sheet width.

4. Cooling: The pet palstic sheets are cooled, usually by air or water, to solidify the material and maintain its shape.

5. Trimming and Slitting: After cooling, the edges of the sheets are trimmed, and they are cut into desired widths, resulting in rolls of PET plastic sheet rolls.

6. Quality Control: Samples from the production batch undergo testing for thickness, clarity, strength, and other specifications to ensure quality standards.

7. Packaging and Shipping: The finished PET plastic sheet rolls are packaged for shipment, ensuring protection against moisture and physical damage.

pet-sheet.comを選ぶ理由

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM