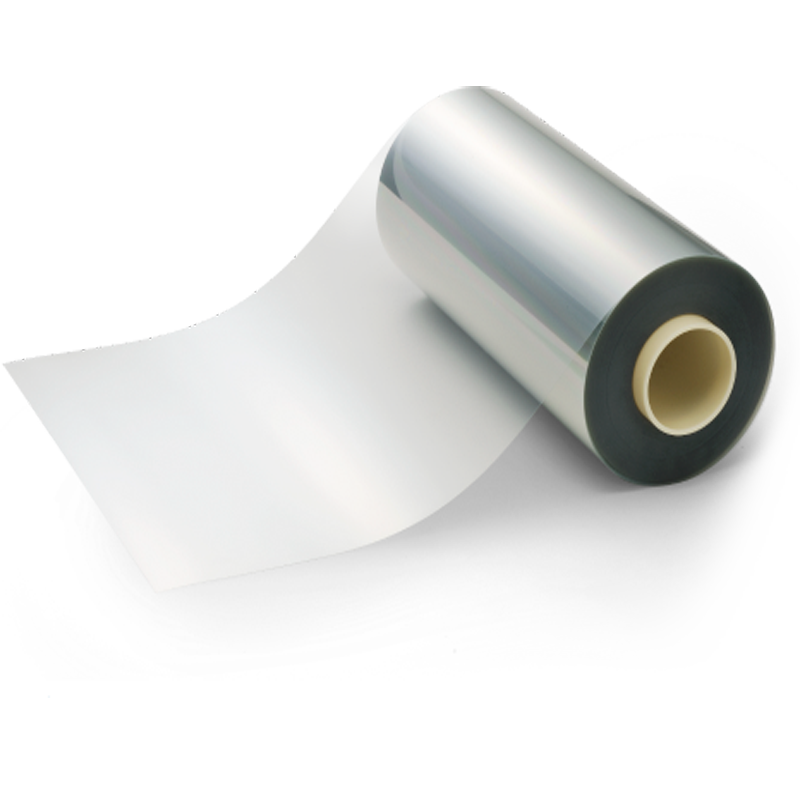

PET ESD Conductive Plastic Roll

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

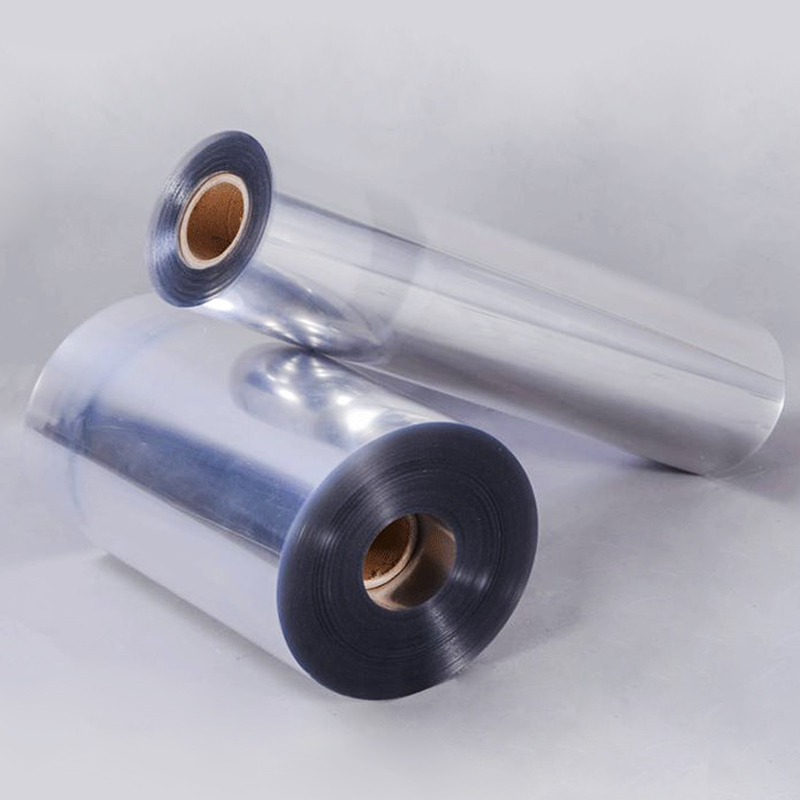

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

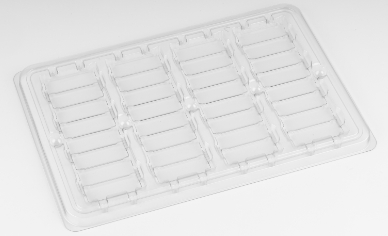

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? ESD Antistatic PET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 ESD Antistatic PET Sheet Roll 熱成形またはブリスター包装用. に関して "PET ESD Conductive Plastic Roll", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction Of PET ESD Conductive Plastic Roll

PET ESD Conductive Plastic Roll is a specialized material designed for use in environments where electrostatic discharge (ESD) can pose a risk. Here’s an overview of its key features and applications:

Key Features Of PET ESD Conductive Plastic Roll

1. Material Composition

PET (Polyethylene Terephthalate): Known for its strength, durability, and resistance to various chemicals.

Conductive Additives: Incorporated into the PET to impart ESD properties, helping to dissipate static electricity safely.

2. ESD Protection

Electrostatic Discharge (ESD) Protection: Essential in electronics manufacturing and handling, where uncontrolled static discharge can damage sensitive components.

Surface Resistivity: Typically designed to have a surface resistivity in the range of 10^6 to 10^9 ohms, balancing conductivity and insulation.

3. Mechanical Properties

Durability: High tensile strength and impact resistance.

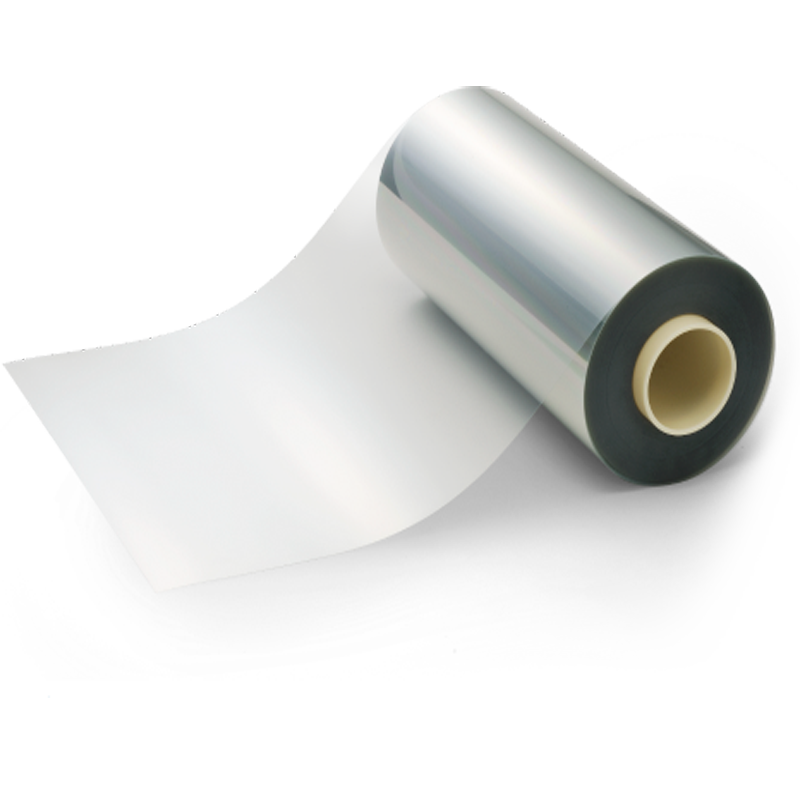

Flexibility: Can be easily cut, formed, or laminated.

Chemical Resistance: Resistant to most chemicals, oils, and solvents, making it suitable for various environments.

4. Transparency

Often available in clear or slightly tinted forms, allowing for visual inspection of packaged items.

Applications Of PET ESD Conductive Plastic Roll

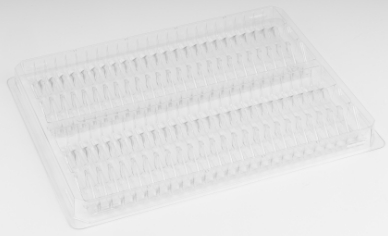

1. Electronics Packaging

Component Trays and Carriers: Safely transport and store electronic components, preventing damage from static discharge.

Tape and Reel Packaging: Used for surface-mount device (SMD) packaging in automated assembly lines.

2. Cleanrooms

Equipment Covers: Protect sensitive equipment and components in cleanroom environments packing.

Workstation Mats: Used on workbenches to provide a static-safe working surface.

3. Automotive Industry

Sensor Packaging: Protect automotive sensors and electronic modules during manufacturing and assembly.

Interior Components: Used in ESD-sensitive areas of vehicle interiors product packing.

4. Medical Devices

Device Packaging: Ensure that static-sensitive medical devices are protected during shipping and storage.

Laboratory Equipment: Used in the construction of ESD-safe lab equipment and tools packing.

5. Industrial Applications

ESD-Safe Containers: Storage bins and containers for static-sensitive materials and components.

Product Parameter Of PET ESD Conductive Plastic Roll

ESD (electrostatic discharge) materials:

| Material | Surface resistance (Ω/sq) | Characteristic |

| Conductive | 104 to 106 | Conductive materials have low resistance, so electrons can easily flow through the surface or inside of these materials. The charge will flow to the ground or another conductive object in contact with the material. |

| Static dissipation | 106 to 109 | Compared with conductive materials, static dissipative materials can make charge flow to the ground or other conductors in a more controlled and slow manner. |

| Anti-static | 109 to 1011 | Anti-static materials can inhibit friction and electricity generation. |

Physical Characteristics of PET ESD Conductive Plastic Roll:

| Properties | Method(ASTM) | Unit | APET | GAG | |

|---|---|---|---|---|---|

| Melting Point | (DSC) | ℃ | 251 | 245 | |

| Glass Transition Temperature | (DSC) | ℃ | 71 | 72 | |

| Deflection Temperature | (DSC) | ℃ | 65 | 70 | |

| Shrinkage | |||||

| 90℃ | Horizonal | D1204 | % | 1.2 | 5 |

| Vertical | 0.5 | 0.4 | |||

| 110℃ | Horizonal | 5 | 4.7 | ||

| Vertical | 2.3 | 2.3 | |||

| Specific Gravity | D792 | g/cm³ | 1.35 | 1.34 | |

| Water Absorption | D570 | % | 0.7 | 0.73 | |

| Tensile Strength At Break | D638 | psi | 8900 | 8280 | |

| Elongation At Break | D638 | % | 471 | 168 | |

| Tensile Modulus | D638 | 10³ psi | 839 | 721 | |

| Hardness (Rockwell) | D785 | R | 70 | 71 | |

| Impact Strength (Dart) | D1790 | J/M | 7200 | 7000 | |

| Flexural Strength | |||||

| Horizonal | D790 | psi | 11200 | 10550 | |

| Vertical | 10800 | 10230 | |||

| Flexural Modulus | |||||

| Horizonal | D790 | 10³ psi | 731 | 684 | |

| Vertical | 719 | 691 | |||

| Surface Resistance Value | |||||

| Conductive | IS | Ω | 10^3~10^6 | 10^3~10^6 | |

| Semic-onductive | IS | Ω | 10^6~10^9 | 10^6~10^9 | |

| Antistatic (ESD) | IS | Ω | 10^9~10^11 | 10^9~10^11 | |

How do I store PET ESD Conductive Plastic Roll?

Storing PET ESD (Electrostatic Discharge) Conductive Plastic Rolls properly is crucial to maintain their properties and ensure their longevity. Here are some guidelines:

1. Environment

Temperature: Store in a cool, dry place. Ideal temperatures range from 15°C to 25°C (59°F to 77°F).

Humidity: Maintain a relative humidity of 50% ± 10%. High humidity can degrade the material, while low humidity can increase static electricity.

Cleanliness: Store in a clean environment free of dust and contaminants to prevent surface damage and contamination.

2. Storage Position

Horizontal Storage: Store the rolls horizontally to prevent deformation and ensure even pressure distribution. Use a suitable support to keep the roll in place.

Vertical Storage: If vertical storage is necessary, ensure the rolls are on a flat, stable surface to prevent tipping and deformation.

3. Protection

Covering: Use protective covers or packaging to shield the rolls from dust, dirt, and light exposure.

Handling: Handle with care to avoid physical damage. Use gloves to prevent fingerprints and other contaminants from adhering to the surface.

4. Avoid Static Accumulation

Grounding: Ensure the storage area has proper grounding to prevent static buildup.

Antistatic Materials: Use antistatic storage racks and bins to further reduce the risk of static electricity.

5. Labeling and Rotation

Labeling: Clearly label the rolls with the date of receipt and other relevant information for easy identification.

First In, First Out (FIFO): Follow FIFO principles to use the oldest material first, ensuring that the stock remains fresh.

By following these guidelines, you can ensure that your PET ESD Conductive Plastic Rolls remain in optimal condition and retain their conductive properties.

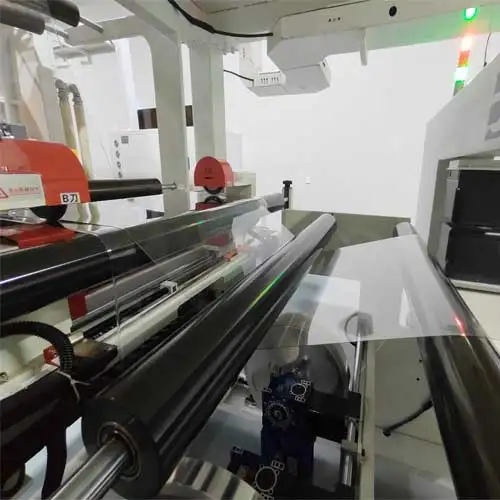

pet-sheet.comを選ぶ理由

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM