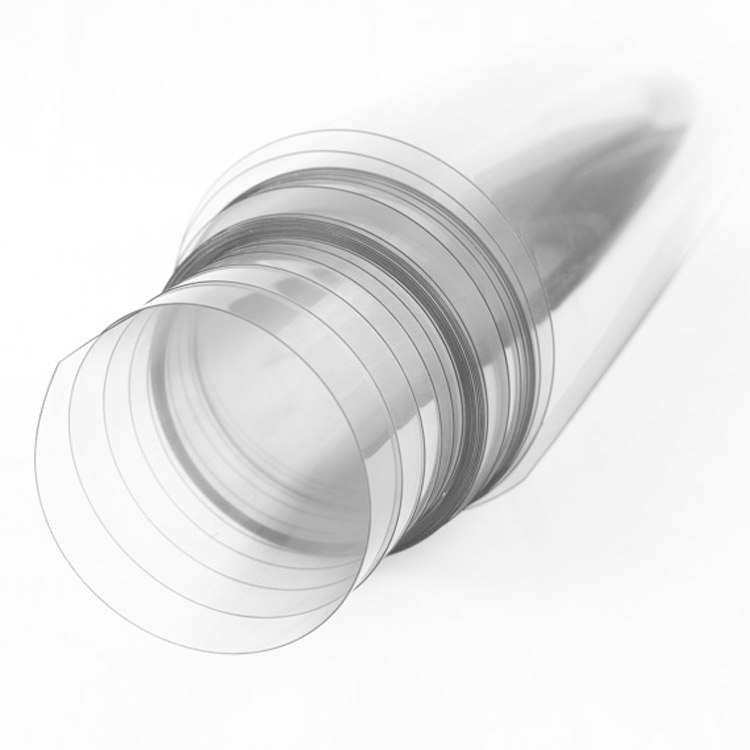

1mm Conductive Transparent PET Plastic Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

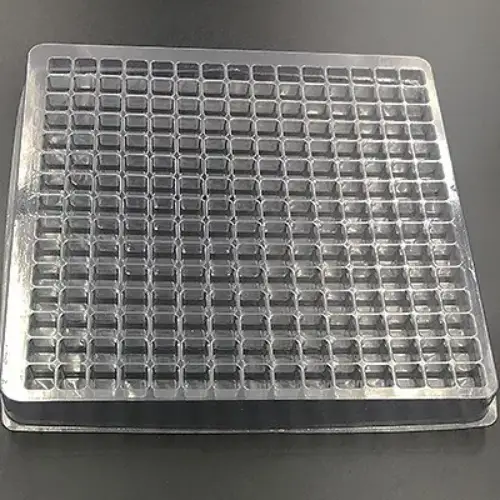

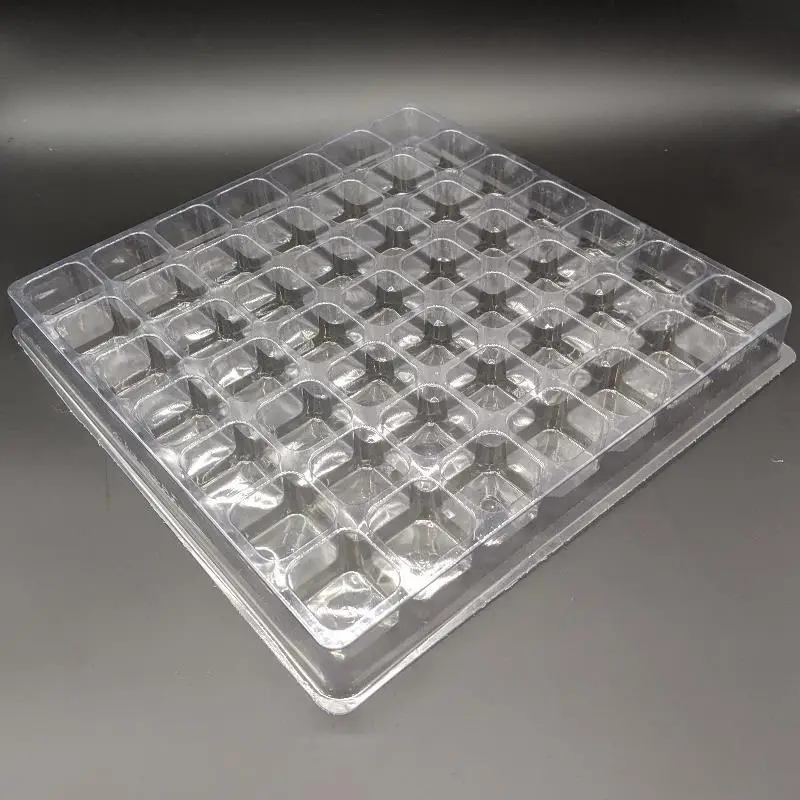

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? Thermoforming PET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 Thermoforming PET Sheet Roll 熱成形またはブリスター包装用. に関して "1mm Conductive Transparent PET Plastic Sheet Rolls", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction of 1mm Conductive Transparent PET Plastic Sheet Rolls

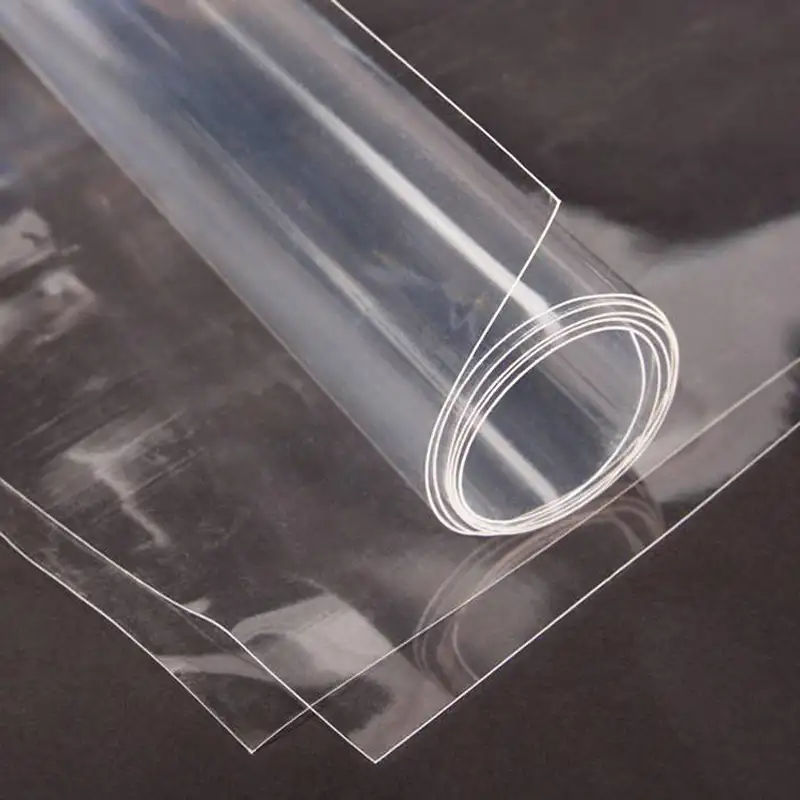

Our 1mm Conductive Transparent PET Plastic Sheet Rolls combine the durability and clarity of polyethylene terephthalate (PET) with surface conductivity, making them ideal for high-performance electronic packaging and EMI shielding applications.

Key Features

Thickness: 1mm

Transparency: High optical clarity

Conductivity: Surface resistance ≤ 10⁶ Ω/sq

Material: Modified PET with conductive coating

Surface Finish: Smooth, anti-static, dust-resistant

Width & Roll Length: Customizable to meet your specifications

Performance Advantages of 1mm Conductive Transparent PET Plastic Sheet Rolls

1. Excellent Surface Conductivity

Effective in dissipating static electricity, suitable for ESD-sensitive components.

2. Superior Transparency

Maintains visibility for display windows, screen covers, and sensor applications.

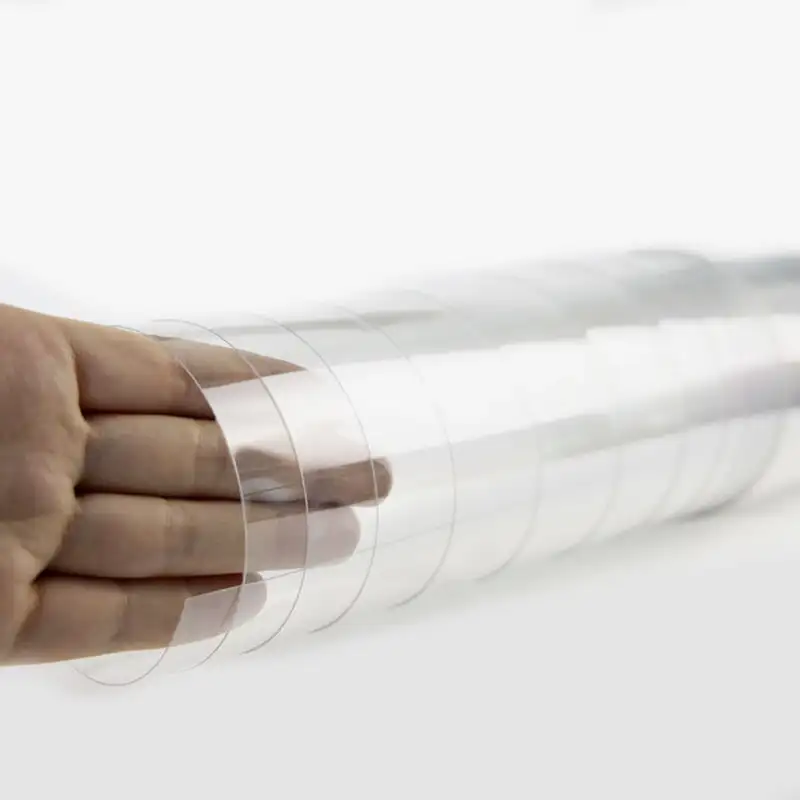

3. Thermoformable

Easy to mold, punch, and cut for blister packaging, tray manufacturing, and electronic enclosures.

4. Chemical Resistance

Withstands exposure to oils, alcohols, and mild acids.

5. Eco-Friendly

Recyclable material with low environmental impact.

Application of 1mm Conductive Transparent PET Plastic Sheet Rolls

1. Semiconductor Chip Packaging

Used for packaging IC chips, wafers, diodes, transistors, etc., to prevent electrostatic damage.

2. Electronic Components Trays

Ideal for anti-static trays or blister trays used with capacitors, resistors, connectors, relays, and other electronic parts.

3. Mobile Phone and Tablet Component Packaging

Used for screen modules, camera modules, and batteries during production and shipping.

4. LCD/LED Display Screen Protection Packaging

Transparent conductive layers help prevent static buildup while providing clear visibility.

5. Hard Drive, Motherboard & PCB Packaging

Protects sensitive components from static discharge during transportation or assembly.

6. Optoelectronic Devices & Sensor Packaging

Perfect for static-sensitive parts such as IR modules, laser devices, and image sensors.

7. Medical Electronic Device Packaging

Suitable for dust-free and anti-static packaging of high-precision medical electronic components.

Parameter of 1mm Conductive Transparent PET Plastic Sheet Rolls

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

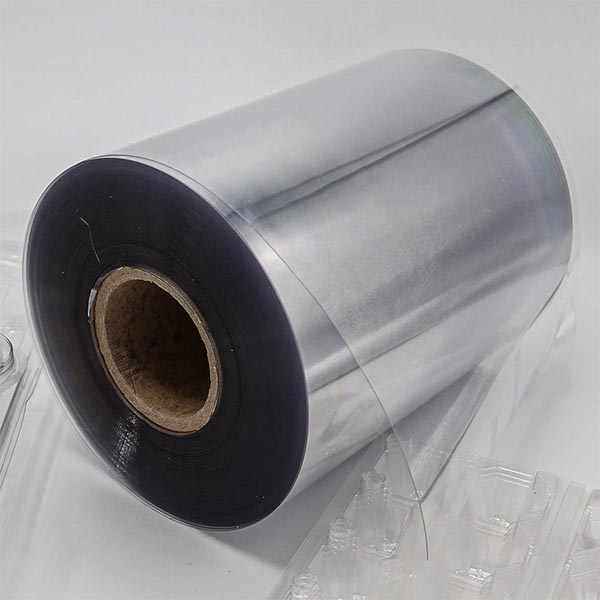

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

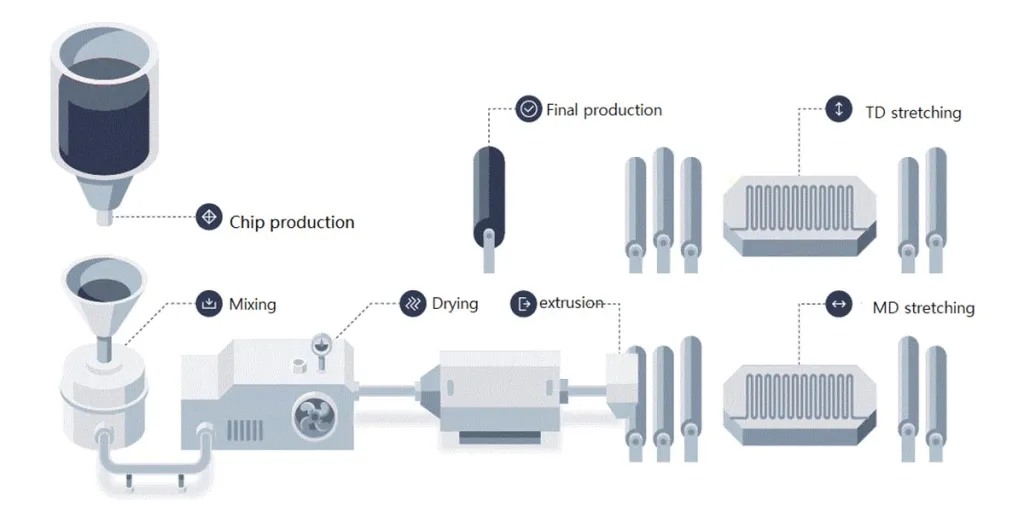

Production Process of 1mm Conductive Transparent PET Plastic Sheet Rolls

1. Raw Material Preparation

- Selection of high-viscosity PET resin (virgin or recycled grade depending on requirements)

- Addition of conductive additives or preparation for surface coating (e.g., ITO, conductive carbon, or polymer layers)

2. Drying

- PET raw material is dried in a dehumidifying dryer at 160–180°C to remove moisture and prevent hydrolysis during extrusion.

3. Extrusion & Sheet Forming

- The dried PET resin is melted in a twin-screw extruder.

- Melt passes through a T-die to form a flat sheet with controlled thickness (1mm).

- Optionally co-extruded with other layers if multilayer structure is required.

4. Quenching & Cooling

- The molten sheet is cooled rapidly on a chill roll to preserve transparency and control crystallization.

5. Conductive Coating (if applicable)

- A thin, transparent conductive layer (e.g., ITO or conductive polymer) is applied via:

- Roll-to-roll vacuum sputtering (for ITO)

- Spray coating or dip coating

- Gravure or slot-die coating

- Followed by drying and curing (UV or thermal).

6. Surface Treatment

- Anti-static treatment or hard coating for scratch resistance (optional).

- Corona treatment or primer coating if adhesion improvement is needed.

7. Thickness & Surface Quality Inspection

- Online thickness gauge (laser or beta-ray) ensures uniformity.

- Visual inspection for optical clarity, bubbles, streaks, or contamination.

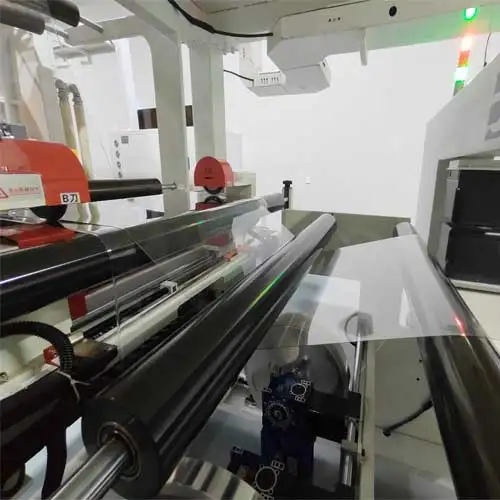

8. Slitting & Rewinding

- The wide sheet is slit into required roll widths and rewound into customer-specified roll lengths.

9. Packaging

- Rolls are packed in anti-static PE film and placed in ESD-safe cartons or pallets.

10. Quality Control

- Final inspection includes surface resistivity testing, haze & light transmittance measurement, and mechanical property checks.

pet-sheet.comを選ぶ理由

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM