1.8 mm Thickness PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- 生産制限:

- 厚さの範囲: 0.18mm-1.8mm

- 幅の範囲: 350mm-1300mm

- 色の範囲: クリア/透明/黒/白/カスタマイズカラー

- MOQ: 5 トン (無料サンプル受付)

- 用途: 熱成形トレイ / 電子トレイ / 生鮮食品トレイ / ブリスター包装

これをお探しですか? Thermoforming PET Sheet Roll. pet-sheet.com is 製造と輸出に特化した工場、硬質 Thermoforming PET Sheet Roll 熱成形またはブリスター包装用. に関して "1.8 mm Thickness PET Plastic Rolls", 日语:PETプラスチックの厚さ、幅、および用途などの要件をお知らせいただければ、当社のプロフェッショナルな営業チームが最も競争力のある価格をご提示します。

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

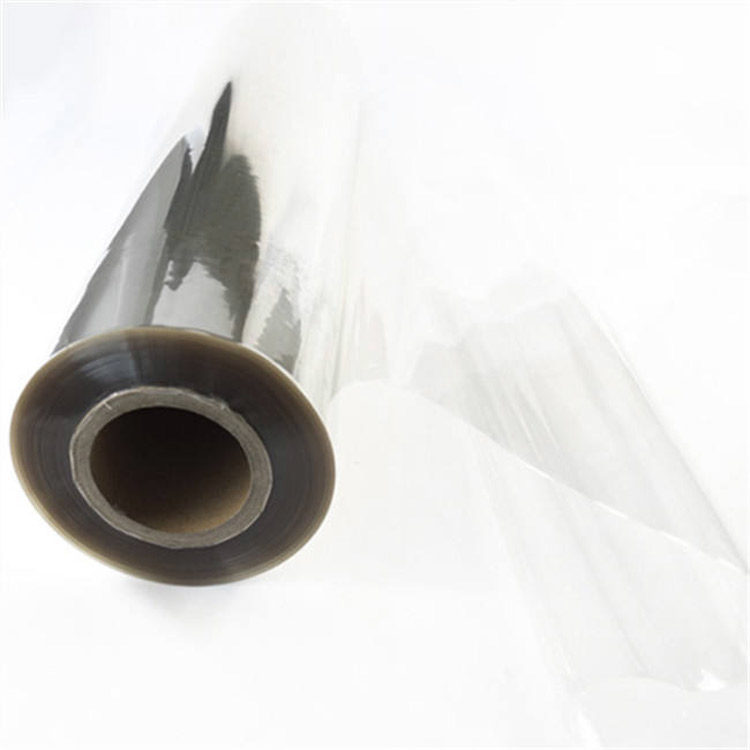

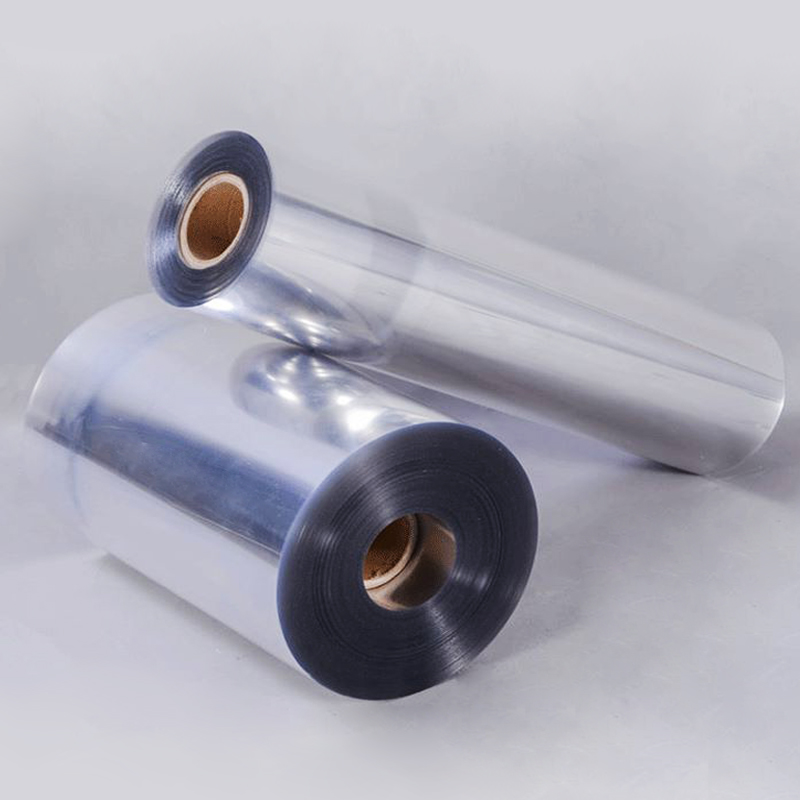

Introduction of 1.8 mm Thickness PET Plastic Rolls

1.8 mm thickness PET plastic rolls. PET is commonly used for packaging materials due to its durability, clarity, and moisture resistance. PET plastic rolls of this thickness can be suitable for various applications.

Polyethylene Terephthalate (PET) is a type of polyester that is widely recognized for its strength, clarity, and versatility, particularly in packaging and industrial applications. PET’s inherent properties make it one of the most popular plastic materials for creating durable and transparent products. When manufactured into 1.8 mm thickness plastic rolls, it strikes an ideal balance between flexibility and strength, providing a range of uses across different sectors.

Applications of 1.8 mm Thickness PET Plastic Rolls

1.Food & Beverage Packaging

PET is widely used in the food and beverage industry due to its excellent moisture and oxygen barrier properties. The 1.8 mm thickness provides durability and strength, protecting the contents from external damage, preserving freshness, and extending shelf life.

Packaging for Fresh Produce: PET rolls can be used to create flexible packaging for fresh produce that allows air exchange while maintaining product quality.

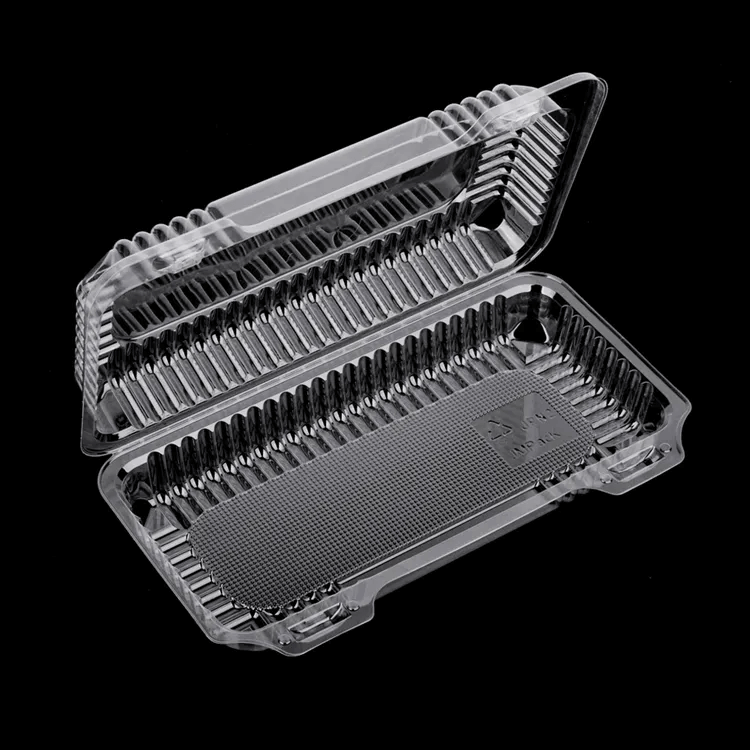

Food Containers & Trays: The 1.8 mm PET thickness is often used in creating trays, containers, and clamshell packages that require structural integrity.

2. Cosmetic & Pharmaceutical Packaging

In the beauty and healthcare industries, packaging often needs to combine clarity with sturdiness. PET plastic rolls with 1.8 mm thickness are ideal for packaging cosmetics, medical devices, and pharmaceutical products, offering visual appeal and chemical resistance.

3. Medical & Healthcare

Medical Packaging: PET is frequently used in packaging medical supplies such as syringes, bandages, and sterile equipment. The 1.8 mm thickness provides the required strength and sterilization capabilities for medical packaging.

Pharmaceutical Blister Packs: 1.8 mm PET is also used in creating blister packs for tablets and capsules, ensuring that the packaging is durable, tamper-evident, and moisture-resistant.

4. Industrial & Commercial Uses

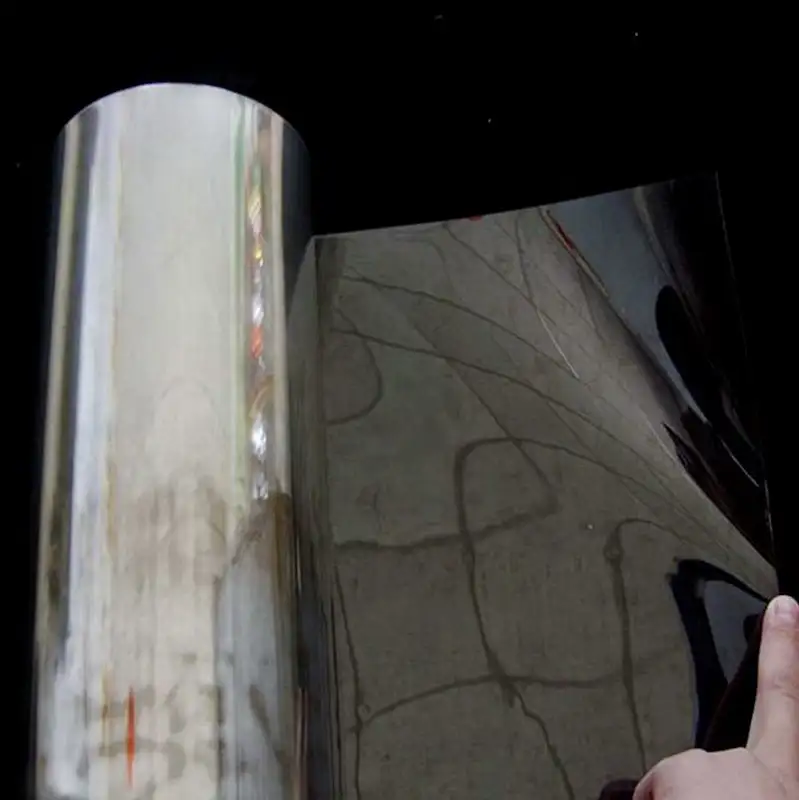

Protective Packing : PET plastic, particularly PET plastic rolls with a thickness of 1.8 mm, are widely used in various protective packaging fields, especially for precision industrial components, electronic products, and surface protection.

Due to the excellent physical and chemical properties of PET, combined with the 1.8 mm thickness, it provides extra protection for delicate products, effectively preventing wear, impact, and external contaminants.

Advantages of 1.8 mm Thickness PET Plastic Rolls

1. Enhanced Durability and Strength

The 1.8 mm thickness of PET plastic rolls provides superior tensile strength, making them resistant to physical wear, impacts, and tears. This added strength makes them ideal for applications where durability is critical, such as in protective packaging for electronics, industrial parts, and fragile products.

2. Impact Resistance

The increased thickness of 1.8 mm ensures the PET material is better able to withstand impacts and punctures compared to thinner films. This makes it highly effective for protecting delicate goods during transportation and storage, minimizing the risk of damage from accidental drops or rough handling.

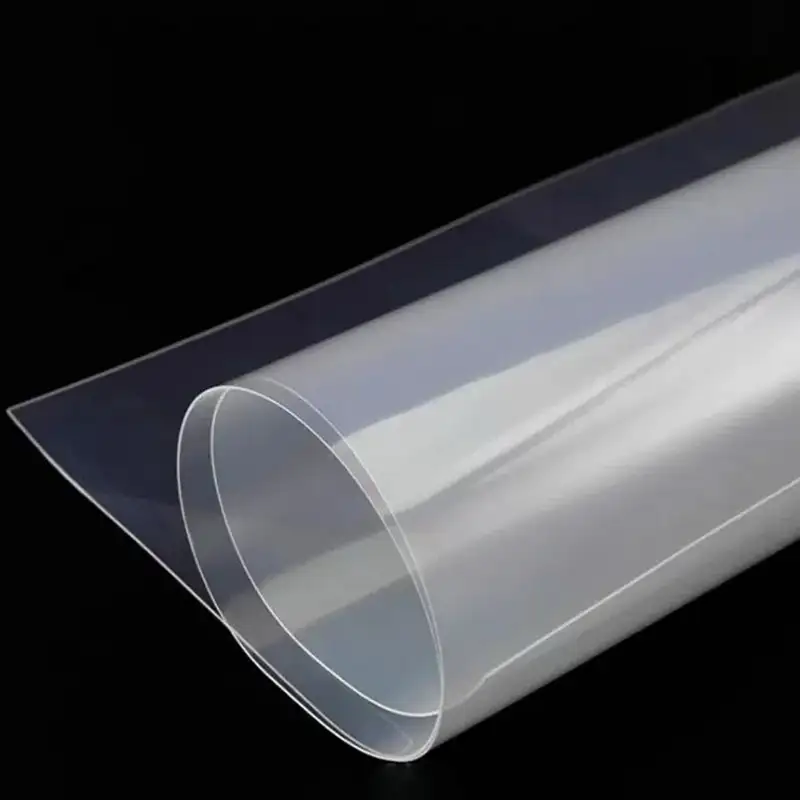

3. High Transparency and Clarity

PET is naturally transparent and provides excellent optical clarity. The 1.8 mm thickness does not compromise the material’s ability to maintain clear visibility, making it ideal for retail packaging or display products where product visibility is important.

4. Moisture and Chemical Resistance

PET is inherently moisture-resistant, which helps protect contents from water damage, making it ideal for packaging products that need to be shielded from humidity. The 1.8 mm thickness adds an extra barrier against moisture and chemicals, offering more protection for sensitive items.

5. UV Resistance

PET has natural UV resistance, which helps protect items from sunlight exposure that could cause degradation or fading. This is particularly beneficial for products stored or displayed in areas exposed to direct sunlight, such as outdoor signage or retail displays.

6. High Flexibility with Added Thickness

While thicker than standard films, PET with 1.8 mm thickness still retains a degree of flexibility, allowing it to be thermoformed, die-cut, or heat-sealed without compromising structural integrity. This flexibility is important for customizing packaging solutions.

7. Sustainability and Recyclability

PET is recyclable, and the 1.8 mm thickness still allows the material to be repurposed effectively. Recycled PET (rPET) can be used to create a wide variety of new products, reducing waste and promoting sustainability.

8. Protection Against Dust, Dirt, and Contaminants

With its smooth surface, 1.8 mm Thickness PET plastic rolls offer protection against dust, dirt, and other contaminants, which is crucial when packaging sensitive items such as electronics, medical devices, or food products.

9. Heat Resistance

PET is known for its heat resistance up to certain temperatures, and the thicker 1.8 mm version adds additional stability when used in environments with temperature fluctuations, making it ideal for products that require heat protection during handling, shipping, or storage.

10. Cost-Effective Solution

Despite being thicker, PET remains a cost-effective option for protective packaging. The durability and strength provided by the 1.8 mm thickness help reduce the need for additional packaging materials, resulting in long-term cost savings and efficient protection.

11. Customizability

1.8 mm Thickness PET plastic rolls are easy to customize in terms of size, shape, and design, making them suitable for a wide range of applications, from food packaging to industrial parts protection. They can also be printed on with ease for branding or product information.

12. Improved Structural Integrity for Packaging:

The thicker 1.8 mm material ensures that packaging retains its shape and structure over time, even during rough handling, providing better overall protection and more attractive packaging solutions for various industries.

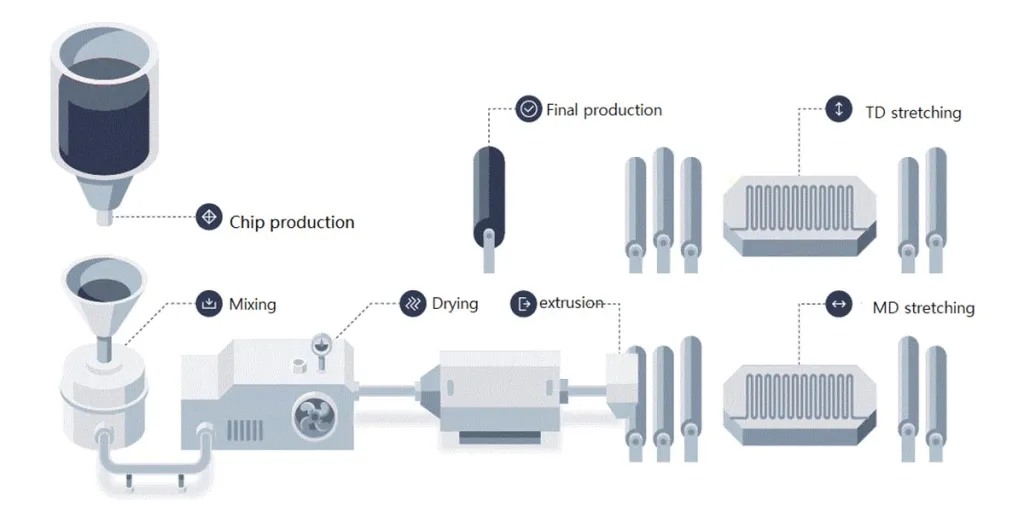

Processing Flow of 1.8 mm Thickness PET Plastic Rolls

The processing flow of 1.8 mm thickness PET plastic rolls involves several key stages:

1. Polymerization: PET resin is created by polymerizing terephthalic acid (TPA) and ethylene glycol (EG) to form PET pellets.

2. Extrusion: The PET pellets are melted and extruded through a die to form a continuous sheet of PET.

3. Cooling: The extruded sheet is rapidly cooled to solidify it into a flexible film.

4. Stretching: The film is bi-axially stretched (both lengthwise and widthwise) to improve strength, clarity, and barrier properties.

5. Annealing: The stretched film is heated in an oven to relieve internal stresses and enhance stability.

6. Slitting and Rolling: The film is cut into the desired width and wound into rolls of 1.8 mm thickness.

7. Surface Treatment (optional): Surface treatments like corona discharge may be applied to improve printability or adhesion.

8. Quality Control: The final rolls are inspected for thickness, clarity, and consistency to ensure they meet specifications.

9. Packaging and Distribution: The finished PET plastic rolls are packaged and prepared for shipment.

This flow ensures the production of high-quality, durable PET plastic rolls with consistent properties for various applications.

Why Choose 1.8 mm Thickness PET Plastic Rolls?

1. Durability: PET is known for its robust physical properties, including its high tensile strength and impact resistance. It is a tough material, resistant to cracking, chipping, and breaking, which makes it ideal for creating long-lasting products. The 1.8 mm thickness adds extra protection, making it suitable for applications that require additional strength or safeguarding.

2. Transparency and Clarity: PET is inherently transparent, offering a high level of optical clarity. This makes it the go-to material for applications where visibility is critical. Whether it’s showcasing a product in packaging or creating display items, PET provides a crystal-clear finish that enhances the product’s visual appeal.

3. Moisture Resistance: PET’s moisture resistance is one of its standout qualities. It does not absorb moisture, preventing mold, mildew, and bacterial growth. For industries that rely on packaging sensitive items like food, pharmaceuticals, and electronics, PET’s moisture barrier helps to preserve the quality and shelf life of the product.

4. Chemical Resistance: 1.8 mm thickness PET plastic roll is chemically inert to most oils, greases, solvents, and mild acids, making it suitable for packaging products that may be exposed to chemicals. The 1.8 mm thickness adds to its chemical resistance, ensuring it remains intact and stable even when in contact with certain substances.

5. Lightweight: Despite its strength, 1.8 mm thickness PET plastic rolls are relatively lightweight material, which makes it ideal for packaging solutions. This is particularly important in shipping and transportation where minimizing weight can reduce costs.

6. Environmental Considerations: PET is recyclable, and many manufacturers use recycled PET (rPET) to produce new products, thus reducing the material’s environmental impact. Additionally, PET can be repurposed into a variety of other products, such as clothing fibers, bottles, and construction materials, further contributing to sustainability efforts.

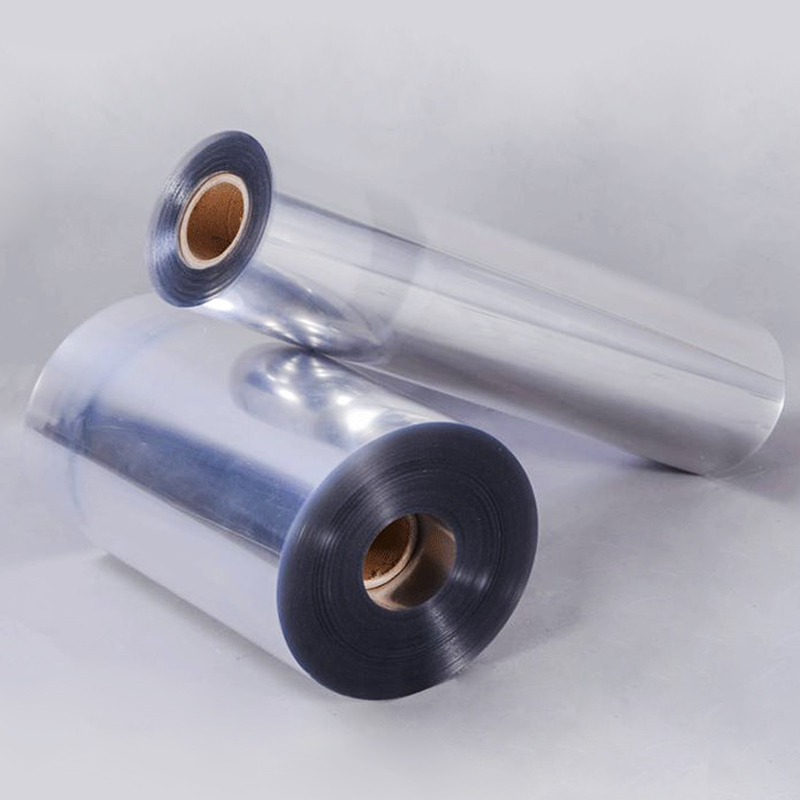

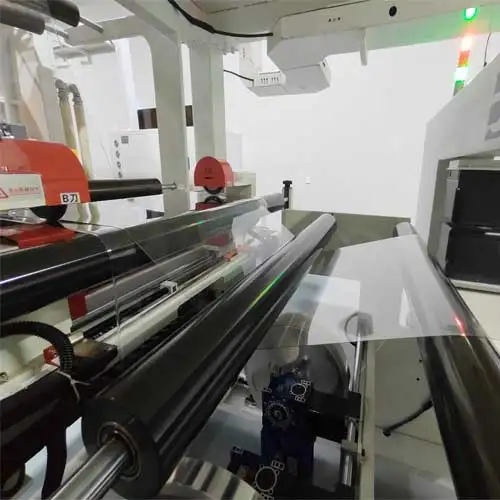

1.8mm thickness PET plastic rolls production line

1.8mm thickness PET plastic rolls are widely used in various protective packaging fields due to their high strength, transparency, anti-pollution and thermal stability.

Whether used to protect electronic products, precision mechanical parts, or for home appliances and sensitive surface protection, 1.8mm PET plastic rolls provide excellent anti-damage, moisture-proof and anti-pollution functions, ensuring that the packaged items remain intact during transportation and storage.

In addition, as an environmentally friendly and recyclable material, PET also has obvious advantages in green environmental protection.

pet-sheet.comを選ぶ理由

共押出生産

共押出生産

品質検査

品質検査

安全な梱包

安全な梱包

納期について

納期について

PET-SHEET.COMへのお問い合わせ

当社のプロの営業スタッフと技術者は、お客様の特定のアプリケーションに対して製品の最終的な特性と材料ソリューションを決定し、お客様に見積もりと詳細なスケジュールを提供します。 当社のプロの営業チームに連絡するには、フォームに記入してください。- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM